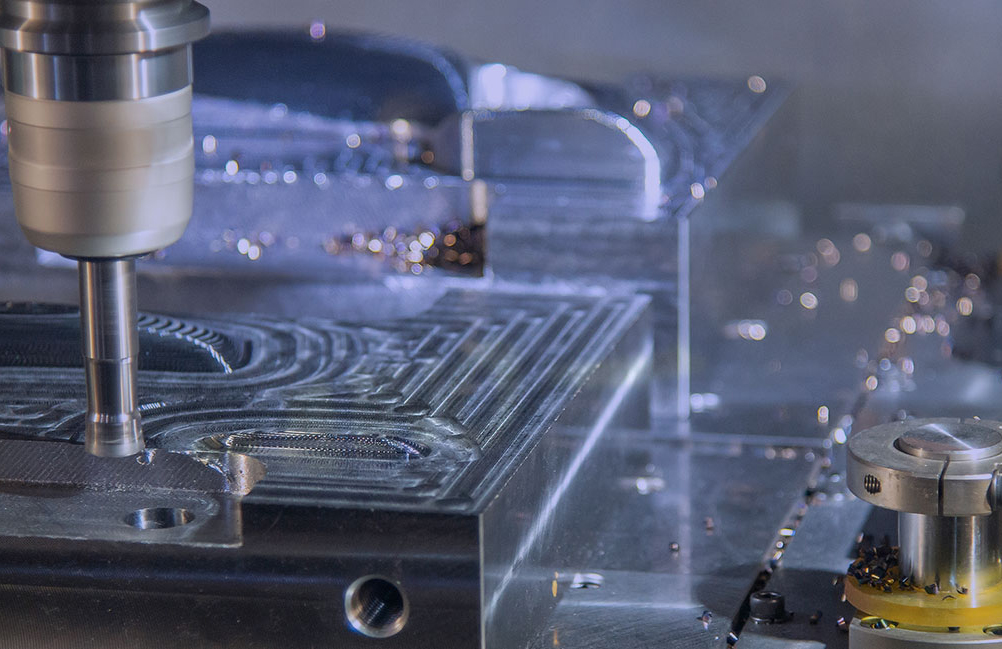

MINO always puts quality assurance and technology innovation in the first place of enterprise development. MINO China has inherited Mino Industry's 70 years of aluminum die-casting technology and experience, and we strive for excellence in technology and quality. MINO has own unique core competitiveness in ultra-thinning of die-casting technology, downsizing, vacuum and precision machining, cleaning, assembly, automation integration via information sharing between groups. MINO pays attention to talent training and has an independent R&D team. We advocates joint development with customers, from product design, die-casting solution, mould manufacturing to foundry, machining and assembly, we can provide a comprehensive solution, cooperating with customers to win the market by technology.

Develop Auxilary Tools

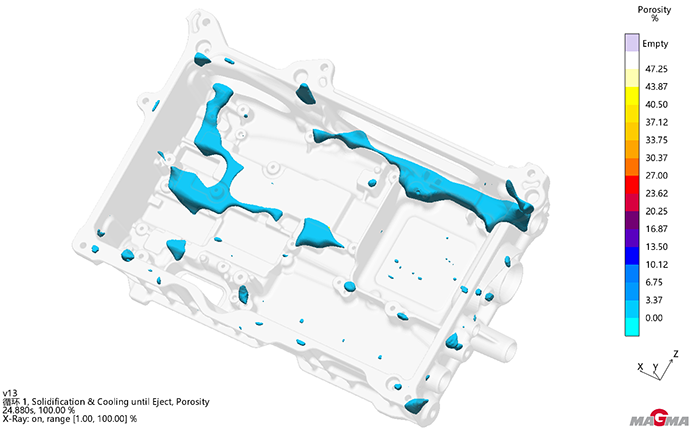

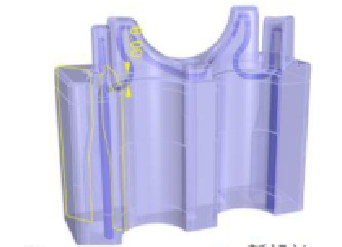

Own development auxilary tools MAGMA/AUTO CAD/UG/PRO-E. Use MAGMA to implement CAE flow analysis, can identify product risk area in pre-design phase, use high-resolution metallographic instruments to achieve max 1000x magnification, further analysis and improvements were made by observing the microstructure of the gold body in order to reach scheme optimization of die-casting solution.

Development Technology

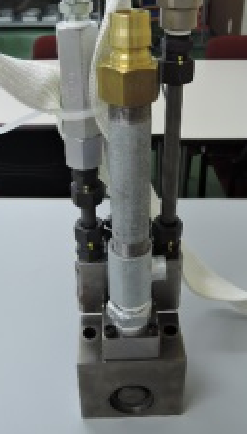

Use different types of vacuum valves and local extrusion techniques, achieving development and mass production of products with partial thicker wall thicknesses and higher requirements. Enhance cooling through 3D printing technology of mold part, can improve the overheating of the local structure in the mold. Use oil thermometer and thermometer to control mold temperature effectively, specialized for thin-walled parts development, and it helps to improve the forming of thin-walled parts.

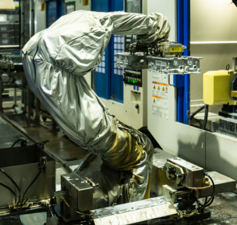

Achieve effiency, combination, intelligence through one-piece flow layout(or machining island), process improvement standardization, PCD tool applications, workpiece landing inspection, cutting torque monitoring technologies.

Reach max 0.3mm products particles through ultrasonic, high-pressure fixed-point cleaning and vacuum dryer integrated technology to remove cutting fluids, oil, aluminum chips and burrs. Reduce the risk of component leakage through vacuum die-casting technology. 100% on-line automatic airtightness inspection by air or helium, the leakage amount data is stored and backed up to prevent defectiveness outflow. In the internal negative pressure environment, the tube of new energy OBC components can be pressed in, FIPG automatic glue, automatic image detection, bolt assembly, torque monitoring, ensure product quality.